Thermo Heater

NH Series

| Model | Output |

|---|---|

| NH-10 | 116 kW |

| NH-20 | 233 kW |

| NH-30 | 349 kW |

| NH-40 | 465 kW |

| NH-60 | 698 kW |

| NH-80 | 930 kW |

| NH-100 | 1,163 kW |

| NH-125 | 1,453 kW |

| NH-150 | 1,744 kW |

| NH-200 | 2,326 kW |

| NH-250 | 2,907 kW |

| NH-300 | 3,488 kW |

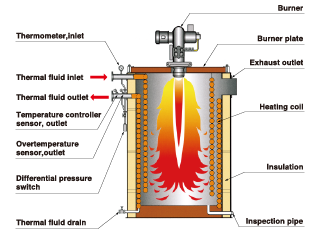

High temperatures at atmospheric pressure

A thermal oil boiler “Thermo Heater” uses thermal oil instead of water, which generates pressure at temperatures above 100℃, and the pressure rises sharply, such as about 4 MPa at 250℃ and about 15 MPa at 340℃. This means that in a steam heating system, your plant must be equipped with high-pressure equipment, and strict safety devices and water treatment are required, but this is not necessary for the Thermo Heater.

Low operating costs

Since thermal oil is circulated and utilized indirectly in a closed system, there is no loss resulting from such as leakage, flash, blowdown and drainage (which typically cause 10-15% loss), and operating costs are low because the electrical power required during operation is minimal.

Uniform heating

Since thermal oil is used in the liquid phase, a small pipe diameter is sufficient for the Thermo Heater, and the temperature of the thermal oil hardly drops even in long-distance piping. It also prevents uneven temperatures and ensures uniform heating.

Precise temperature control

The Thermo Heater can control temperature easily, freely and precisely.

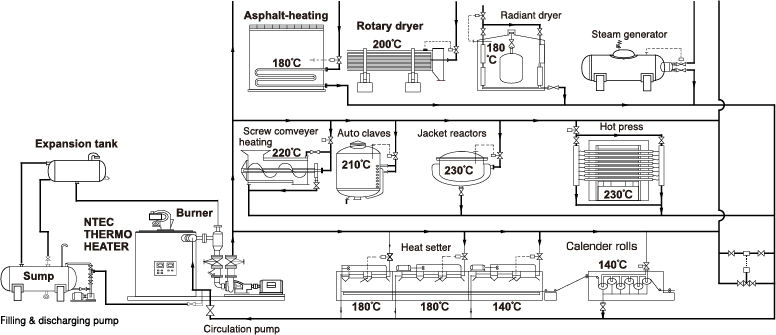

Available for many applications

The Thermo Heater can be used for many applications with different temperature conditions and also for both oil heating and oil cooling.

Other various specifications also available

- 390 spec. for silicon high-temperature thermal oil

- Boiler with an air preheater recovering heat from exhaust gas (improved efficiency up to 92% depending on conditions)

- Boiler with a dual fuel (oil/gas) burner

- Boiler using by-product oil and by-product gas as fuel, etc.